Machine workshop

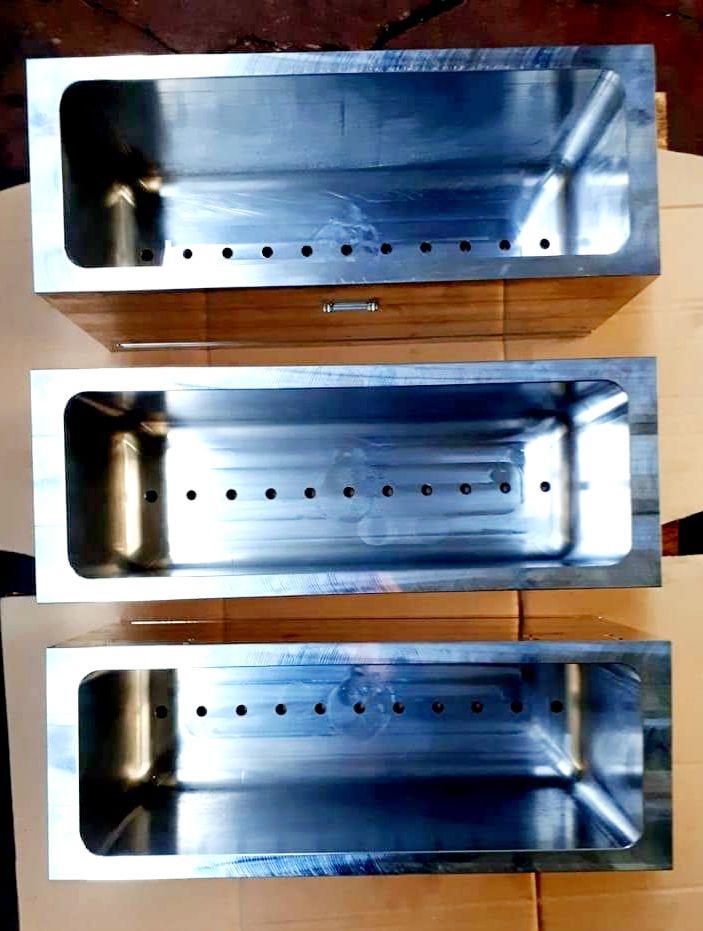

CBR is specialized in precision machining, it uses modern numerical control machinery. The process consists in the realization of mechanical parts as per customer's drawing.

Machining operations can be performed on every material type commercially available, from stainless steel to plastics, brass, bronze, aluminium in all its alloys, improved steels and cast iron.

Thanks to all these processes, we can meet the demands coming from the most different industries.

The targets of CBR are quality and flexibility, in order to achieve full customer satisfaction.

The company can offer:

-

Estimates in 48 hours

-

Milling and turning CN also on very small series (10-20 pieces)

-

Station CAD /CAM processing of complex forms on CNC

-

Machining on behalf of third party contractors

-

Precision mechanical machining

-

Shaft-type

-

Milling metals

-

Turning metals

-

Construction of mechanical particulars as per drawing

Plants and machineries

-

N. 1 machining centre MORI SEIKI NV5000 &1Bt 40 workspace x1020y510z510

-

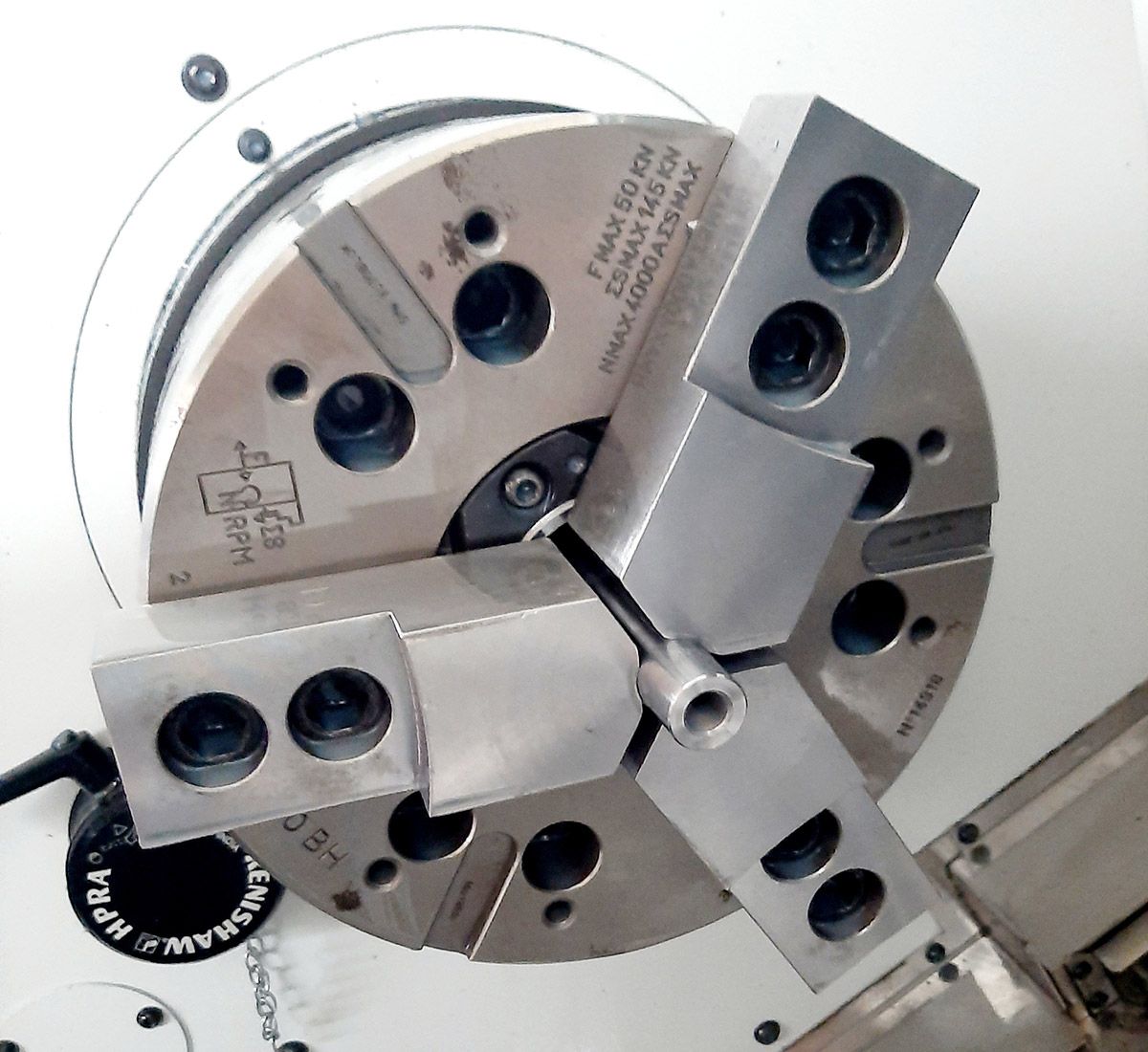

N. 1 lathe CMZ TBI 520mc with C axis and driven tools

Max turning diameter 340 mm – Max length 1000 mm -

N. 1 lathe CMZ TA25Y 640 with live tailstock Y axis and driven tools

Max turning diameter 300 mm – Max length 600 mm -

N. 1 drill with synchronized thread SERRMAC

-

N. 1 model hacksaw SHARK 332 NC Evo MEP

Workable dimensions: Round 200mm max / Square 200mm max / Rectangular 300x200mm max

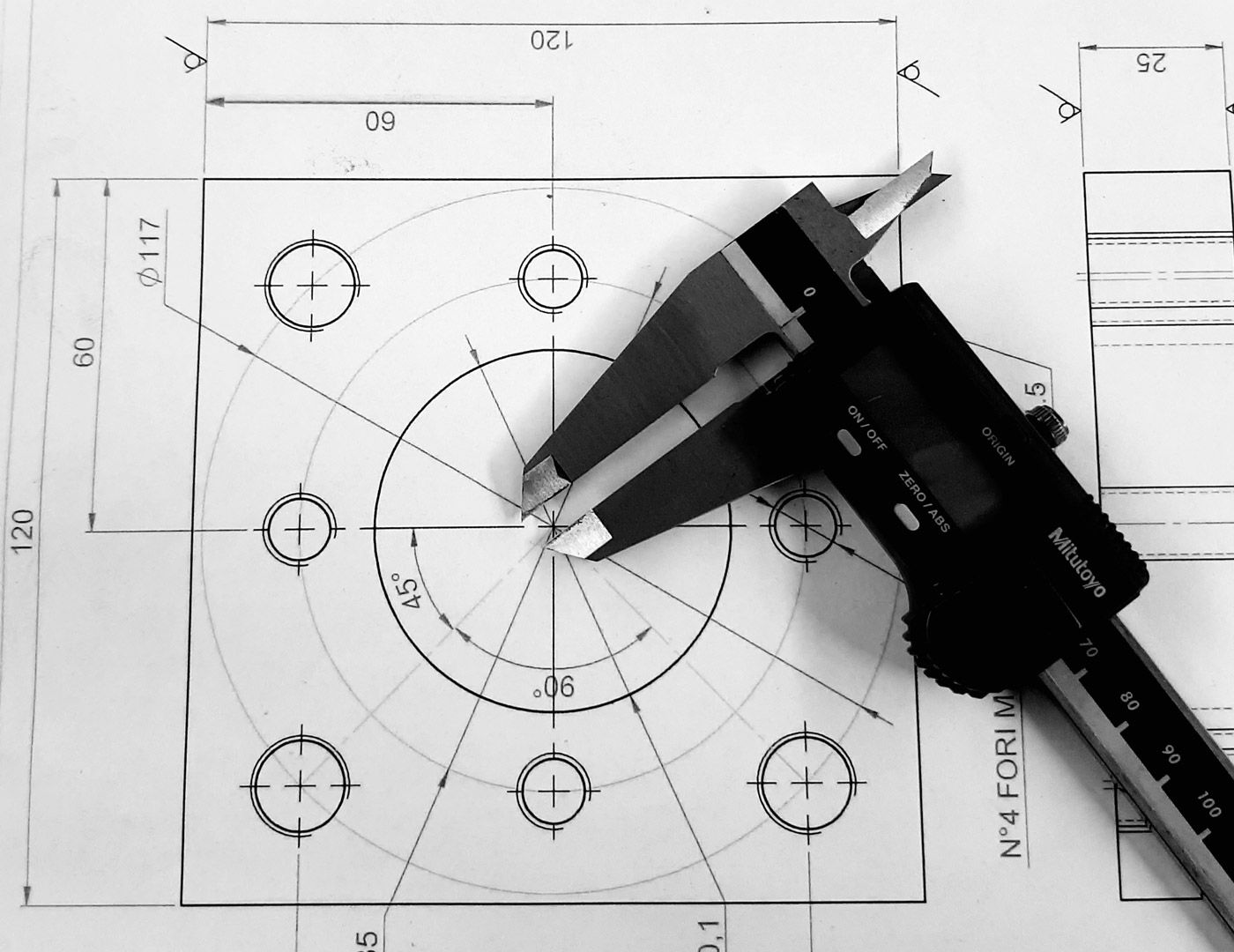

Measuring instruments

-

N. 1 probe 3D – Resolution 0,01 mm

-

N. 1 serie of ceramic blocks Johnson grade 1

-

Series of micrometers range from 0 to 150 mm resolution 0,01 mm

-

Series of micrometers range from 0 to 300 mm resolution 0,01 mm

-

Bore gauges for internal measuring range from 18 mm to 150 mm

-

Standard resolution 0.01mm

-

Digital calipers MITUTOYO

Tools for design and development

-

CAD / CAM

-

Milling and turning on 2-axis, 2-axis and a half

-

Milling with 3d possibility on CNC 3 axis